-

Product DescriptionCompany Info.<>

- Types:

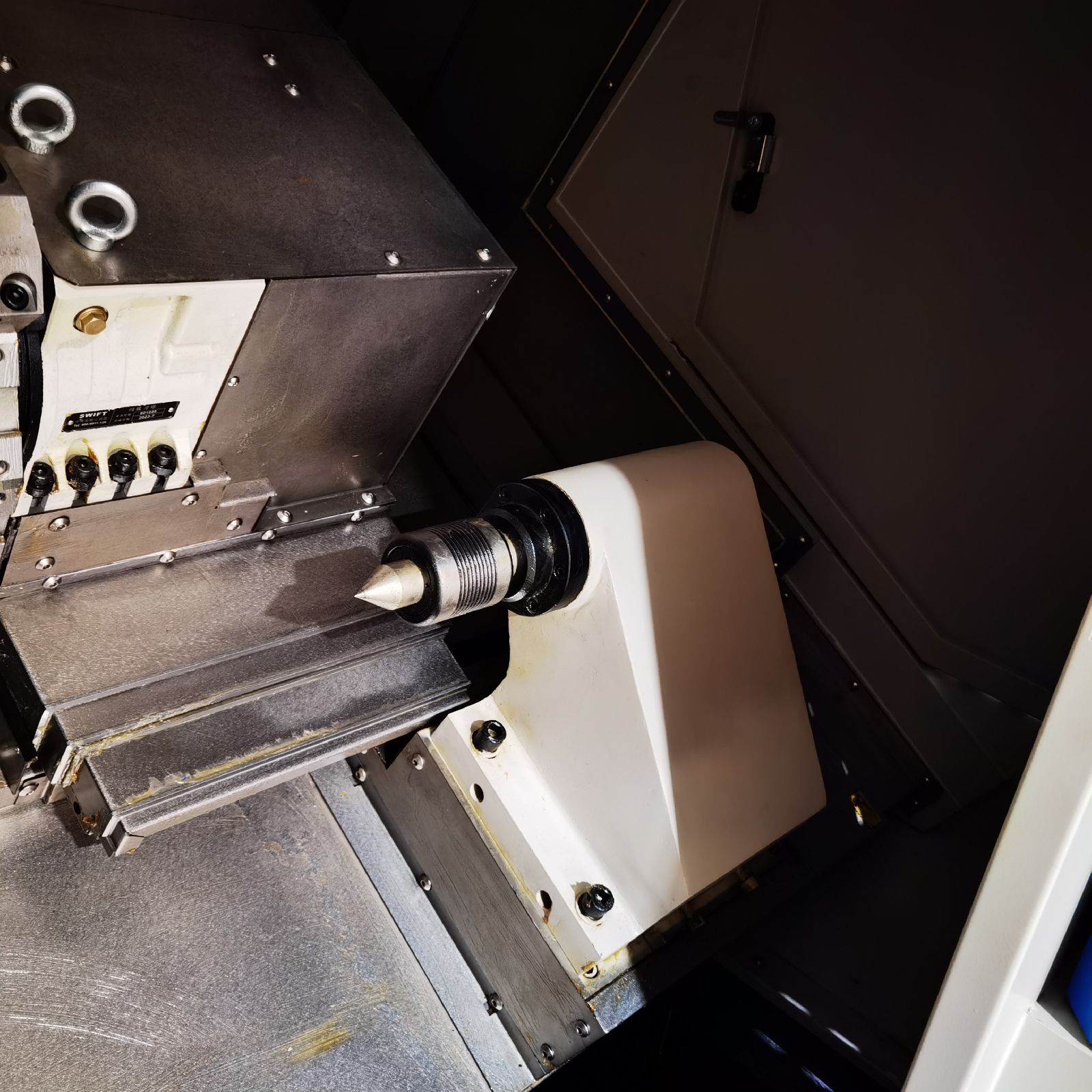

- CNC lathe

- Control form:

- Numerical control

- Layout form:

- Horizontal type

- Model:

- XZ-E500M

- Main motor power:

- 7.5-11 kw

- Overall dimension:

- 2500x1800x1950 mm

- achining accuracy:

- High precision

- Maximum processing length:

- 500 mm

- Maximum machining diameter:

- 300 mm

- Maximum swing diameter:

- 500 mm

- Spindle speed series:

- Stepless

- Diameter of through hole of spindle:

- 52 mm

- Installation form:

- Landing type

- Applicable industry:

- General purpose

- Power type:

- Combined drive

- Applicable scope:

- General purpose

- Inventory or not:

- Yes

Xiezhong intelligent, Dongguan lathe, intelligent lathe, CNC lathe, Guangdong Xiezhong factory direct sales.Machine tool operating conditions

The machine tool shall be suitable for use in the actual environment and operating conditions specified below:

Supply voltage: 10% of rated supply voltage±

Power frequency: 50Hz± 0.5 Hz

Ambient temperature: within the range of 5℃~40℃, and the average temperature of 24h shall not exceed 35℃

Relative humidity: less than 75%, humidity change: the principle is that it should not cause condensation

Altitude: below 1000mAtmosphere: free of excessive dust, acid gases, corrosive gases and salts

Should avoid direct sunlight machine tool, or heat radiation machine tool caused by changes in ambient temperature

Prevent the machine tool from abnormal vibration from outside

Installation location away from flammable and explosive materials

Technicalagreements

I. Main technical parameters:

project unit specification remark processing range Bed * Large swing diameter mm Φ500 * Large machining disc diameter mm Φ500 * Large machining shaft diameter mm Φ300 * Large processing workpiece length mm 500 * Diameter of through-hole of big stick mm 52 X/Z axis movement X-axis effective stroke (radius) mm 250 Z axis effective stroke mm 500 X, Z axis fast moving speed m/min 24 X, Z servo motor kw 1.7 principal axis Spindle nose type / A2-6 Spindle through hole diameter mm Φ65 Spindle * High speed r/min 3000 Spindle servo motor power kw 7.5-11 hydraulic chuck Inch 8 Swing cylinder specification Inch 8 working accuracy X, Z axis repeated positioning accuracy mm ±0.002 X, Z axis positioning accuracy mm ±0.003

bed structureLathe structure type / integrally cast X-axis rail specifications mm 30 ball bearings Z-axis rail specification mm 30 ball bearings 6Sliders X-axis screw diameter/pitch mm Φ32/10 Z-axis screw diameter/pitch mm Φ32/10 tailstock Tailstock structure and movement method 30mm ball guide+ cylinder push tailstock stroke mm 430 chuck center distance mm 500 knife tower Servo turret / Taiwan Jingangxin Twelve Station80 Center High tool Tool holder specification mm 25 Boring tool bar specification mm 25 Outline size Length, height and width mm 2500x1800x1950 machine weight kg About3800

II. Basic configuration

Name of accessory specifications and models manufacturer remark numerical control system 6TA-E Taiwan New Generation principal axis A2-6-200 Wenao hydraulic chuck 8Inch Betford X-axis screw 3210 Silver/PMI Z-axis lead screw 3210 Silver/PMI X axis rail 30mm Silver/PMI Z-axis rail 30mm Silver/PMI X-axis screw bearing 20/47-25/62 FAG/SKF standard Z-axis screw bearing 20/47-25/62 FAG/SKF standard cooling installation High voltage multistage450W-380V RESTAT lubricating device 2.0L proton breaker zhengtai master light switch (电灯) NXM-32S zhengtai contactor (switch) LC1D09 220V/LC1D32 220V Schneider relay RXM2LB2BD/RXZE1M2C Schneider scram button XB2BS542C Schneider green button XB2BA31C Schneider red button XB2BA42C Schneider hydraulic pressure station customization Fengchang, Taiwan angling cylinder TGTS852/TFS852 Zhongyi/Coptic entrench whole sealing chengsheng

III. Machine tool accessories:

serial number names typespecification thenumber manufacturer 1 LED machine tool lighting of1 nine 2 Adjusting shim and bolt 1 set domestic 3 Transport Fixtures 1 set domestic 4 caution light of1 nine

IV. Technical data:

1. IFU (electrical part)(Chinese) Electronic data (USB) 2. System Operation Manual (Chinese) Electronic data (USB) 3. Programming Manual (Chinese) Electronic data (USB) 4. Machine tool packing list 1 part V. Machine tool acceptance:

1. Pre-acceptance: The pre-acceptance shall be conducted at Party B's site to inspect the items in the accuracy inspection sheet of the machine tool and process one standard comprehensive test piece of Party B. If all the accuracy meets the requirements, the machine tool shall be deemed as qualified in the pre-acceptance and can be shipped. Comprehensive test pieces and tools shall be provided by Party A. 2. Final acceptance: Final acceptance shall be conducted at Party A's site under the guidance of Party B's personnel, and the commissioning of machine tools shall be completed. Party A shall provide Party B's commissioning personnel with

Facilitating working conditions.

VI. After-sales service(in the contract)

After the whole set of equipment is put into operation, the quality shall be guaranteed for three guarantees, and the quality guarantee period shall be 12 months (calculated from the date of delivery to Party A after the equipment is finally accepted). Any problem caused by Party B shall be covered by the warranty. During the warranty period, under normal use, the quality problem is caused by the equipment itself, and replacement and maintenance are free of charge. After the warranty expires, Party B shall guarantee to provide preferential spare parts and maintenance services for a long time.

Note: NC system warranty shall be executed according to manufacturer's standard

VII. Technical training:

After the machine tool arrives at Party A's factory, Party A shall be responsible for the preliminary preparation work such as unpacking, positioning and debugging of the machine tool. Party B is responsible for debugging the machine tool and training Party A's personnel in operation, programming and maintenance, so that they can program, use and eliminate general electrical and mechanical faults.

VIII. Force majeure accident:(within the contract)

If either party is unable to perform this Agreement due to serious disasters (such as fire, flood, snow disaster, earthquake, etc.) and other irresistible accidents agreed upon by both parties, the party experiencing the above accidents shall immediately notify the other party by fax or cable (at the fastest speed) of the conditions affecting this Agreement, and provide details of the accidents in the form of air express mail, as well as documents proving the extent of performance of this Agreement. This document shall be sealed by the notary department of the party affected by the accidents. The delay caused by the above accidents shall be postponed on the basis of the original delivery date.

IX.Other matters:

1. This technical agreement shall come into force after being signed and sealed by representatives of both parties, and shall come into force simultaneously with the supply contract. Party B shall inform Party A in time of any change in design personnel during the supply periodso as to facilitate technical communication between both parties.

2. This agreement is made in duplicate, one for each party. It shall be an annex to the contract after being signed by the representatives of both parties and shall take effect at the same time as the effective date of the contractand have the same legal effect.

3. Other outstanding matters shall be settled through friendly consultation between the two parties.

- Name(chinese)

- Name(English)

- Guangdong Xiezhong Intelligent Technology Co., Ltd.

- China credit code

- Identity Verification

- Product Category

- milling machinelathegrinderRadial Drilling machine

- Address

-

Dongguan, Guangdong, China

- Nearby port

- Shenzhen

Guangdong Xiezhong Intelligent Technology Co., Ltd. mainly produces and distributes surface grinding machines, CNC grinding machines, Fengbao turret milling machines, CNC lathes, drilling and tapping centers, wire cutting spark machines and other general equipment. The company is a private enterprise integrating design, production, sales and service. The company has independent intellectual property rights of products and the exclusive distribution of multiple brands in Guangdong. Taiwan Jiande Grinder, Taiwan Weiquan Band Saw Machine, Sanguang Spark CNC Wire Cutting Machine, Taizhou Sifang Wire Cutting Machine, Tailifu Radial Drilling Machine, Nanfang Lathes. The company continues to pioneer and innovate in technology, strictly and scientifically manage quality services, and develop together with customers "is the corporate philosophy. Customer satisfaction is the goal and driving force we pursue. The principle of quickly responding to user needs, and provides customers with cost-effective products and Flexible and applicable technical solutions and complete after-sales services. From R & D, manufacturing, management to sales, and after-sales, we strictly implement the corporate quality management system, continue to innovate, improve efficiency, and provide professional, reliable, high-quality, cost-effective products to serve customers around the world. The company's marketing center is located at No. 16, Fudong Fourth Lane, Fuzhushan, Liaobu Town, Dongguan city. Liaobu Town is the central town of Guangdong Province, adjacent to the urban area, and located in the core of the city's Main City, Songshan Lake National High-tech Industrial Park, Tongsha Ecological Park, and Dongguan Ecological Park. Business friends are welcome to visit and guide. We warmly welcome people with lofty ideals to join us and offer suggestions, and hope that your talented people can make the association even more powerful. In the challenging era of new intelligent technology, Xiezhong will continue to make progress, seek innovation, and inspire excellence, and work together with everyone to make progress and create brilliance.- Name(chinese)

- Name(English)

- Guangdong Xiezhong Intelligent Technology Co., Ltd.

- China credit code

- Identity Verification

- Product Category

- milling machinelathegrinderRadial Drilling machine

- Address

-

Dongguan, Guangdong, China

- Nearby port

- Shenzhen

Guangdong Xiezhong Intelligent Technology Co., Ltd. mainly produces and distributes surface grinding machines, CNC grinding machines, Fengbao turret milling machines, CNC lathes, drilling and tapping centers, wire cutting spark machines and other general equipment. The company is a private enterprise integrating design, production, sales and service. The company has independent intellectual property rights of products and the exclusive distribution of multiple brands in Guangdong. Taiwan Jiande Grinder, Taiwan Weiquan Band Saw Machine, Sanguang Spark CNC Wire Cutting Machine, Taizhou Sifang Wire Cutting Machine, Tailifu Radial Drilling Machine, Nanfang Lathes. The company continues to pioneer and innovate in technology, strictly and scientifically manage quality services, and develop together with customers "is the corporate philosophy. Customer satisfaction is the goal and driving force we pursue. The principle of quickly responding to user needs, and provides customers with cost-effective products and Flexible and applicable technical solutions and complete after-sales services. From R & D, manufacturing, management to sales, and after-sales, we strictly implement the corporate quality management system, continue to innovate, improve efficiency, and provide professional, reliable, high-quality, cost-effective products to serve customers around the world. The company's marketing center is located at No. 16, Fudong Fourth Lane, Fuzhushan, Liaobu Town, Dongguan city. Liaobu Town is the central town of Guangdong Province, adjacent to the urban area, and located in the core of the city's Main City, Songshan Lake National High-tech Industrial Park, Tongsha Ecological Park, and Dongguan Ecological Park. Business friends are welcome to visit and guide. We warmly welcome people with lofty ideals to join us and offer suggestions, and hope that your talented people can make the association even more powerful. In the challenging era of new intelligent technology, Xiezhong will continue to make progress, seek innovation, and inspire excellence, and work together with everyone to make progress and create brilliance. -

Send your message to this supplier*From:*To:

Ms. Liuguilian

*Message:

Ms. Liuguilian

*Message:-

Product Categories

Inquiry

-

Copyright © 2003 - 2025 Goepe.com All rights reserved.